Introduction

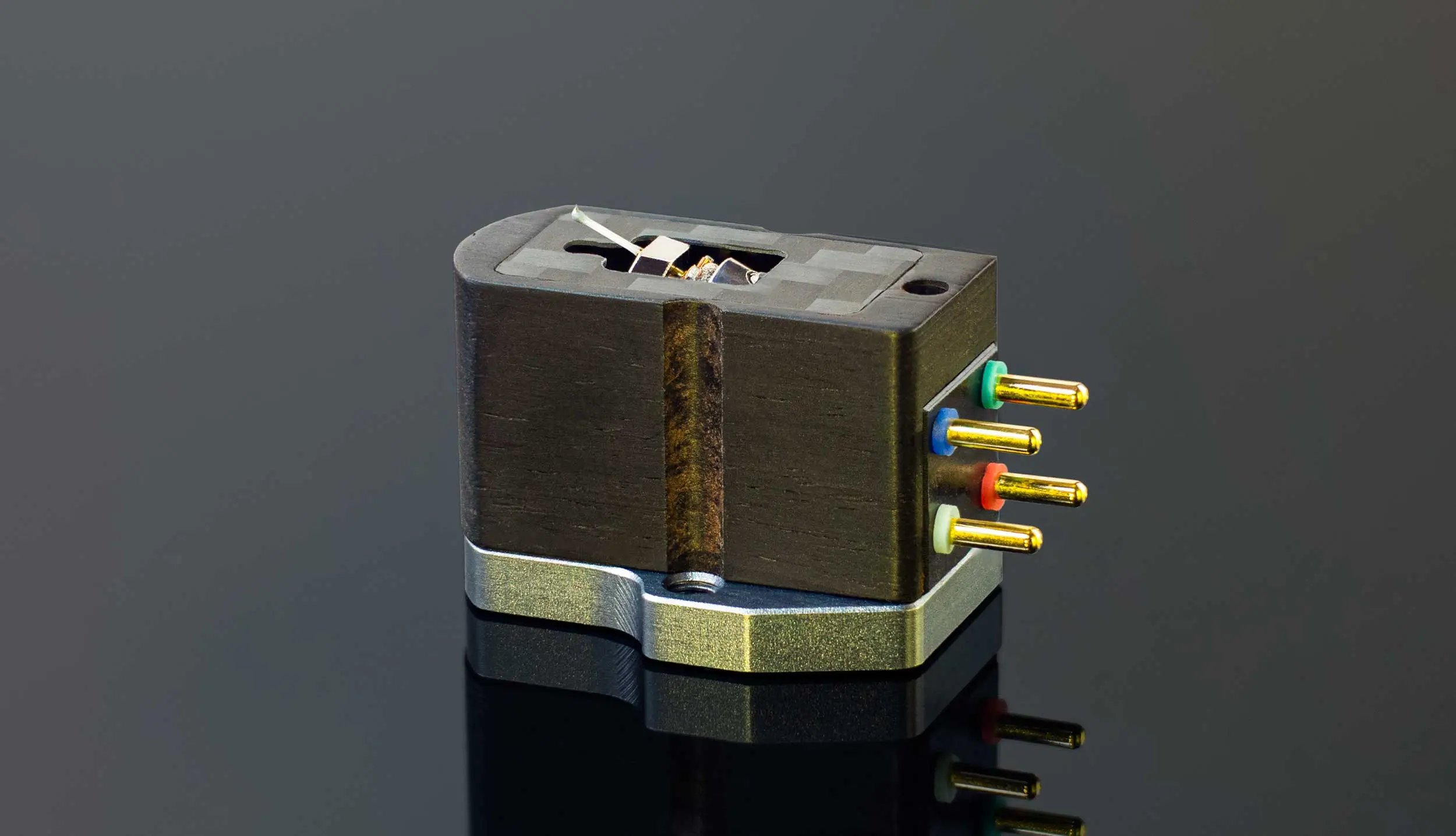

At the heart of every vinyl system lies the phono cartridge. It is a tiny object, easily overlooked, yet it is where the alchemy of analog sound begins. From the microscopic contours of a record groove, the cartridge extracts not just musical information, but the very breath and presence of a performance.

For Analog Lovers — those who cherish the beauty of physical sound and the timeless ritual of vinyl — this is no mere component. The right phono cartridge transforms playback into an experience that stirs the soul. It shapes tone, dynamics, spatial cues, and the emotional force of the music.

Yet the world of phono cartridges is complex. Moving Magnet, Moving Iron, Moving Coil, low and high output, compliance, resonance: each choice matters. And the best choice depends not only on specifications, but on the unique synergy between your turntable, tonearm, phono stage, and your ears.

In this guide, we will explore this fascinating world in depth. Let’s dive in!

The Phono Cartridge: Gateway to the Groove

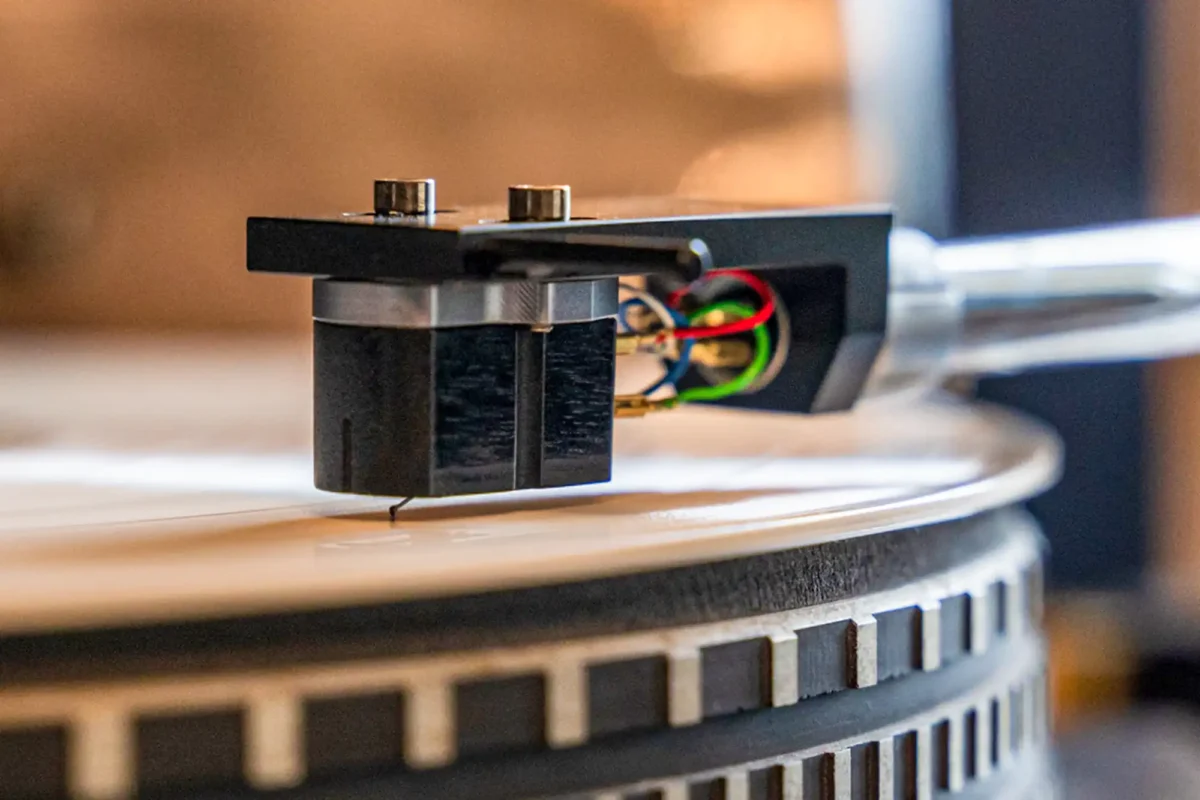

The phono cartridge is the precision transducer mounted at the end of your tonearm. Its task is deceptively simple: to convert the mechanical vibrations of a record groove into an electrical signal that your amplifier can interpret.

But the physical reality is astonishing. The stylus rides in a groove that varies by mere microns. Its velocity, not just displacement, determines the electrical output. Low frequencies produce large groove amplitudes, high frequencies produce rapid stylus accelerations. The cartridge must track all of this with both agility and control.

At the core of every cartridge are four key elements:

-

The stylus, usually diamond, which contacts the groove.

-

The cantilever, which transmits the stylus motion.

-

A generator system, consisting of coils and a magnetic circuit, with the moving element being either a magnet, an iron armature, or the coils themselves.

-

The cartridge body, which provides mechanical grounding and resonance control.

The precision of this system defines the quality of the sound. Tracking ability, transient response, frequency extension, and even perceived timing all originate here.

Generator Principles and Phono Cartridge Types

Main Phono Cartridge Designs

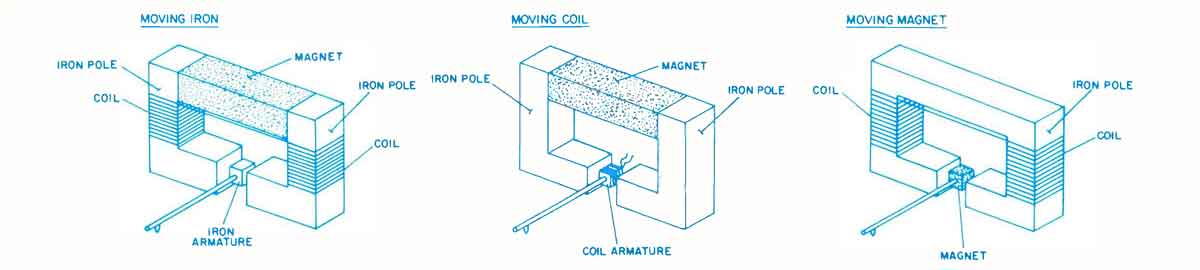

Moving Magnet (MM) Cartridges

In an MM design, the stylus moves a small magnet between stationary coils. This generates a strong electrical signal, sufficient to drive a standard phono input.

MM cartridges are practical and affordable. They allow stylus replacement and offer excellent value. However, they carry a trade-off: the moving mass of the magnet limits transient agility and fine detail resolution compared to the best MC designs.

Inductance Considerations:

MM cartridges typically have relatively high coil inductance. This interacts with the capacitance of the phono cables and the phono stage input to form a resonant RLC circuit. The resonance peak often falls within the upper audible range, shaping the cartridge’s frequency response and sometimes causing audible coloration or loss of extension. Small changes in cable or phono stage capacitance can noticeably affect the sound of MM cartridges, making careful system matching important.

Moving Iron (MI) Cartridges

MI cartridges operate on a similar principle, but instead of moving a magnet or coil, they move a lightweight iron element. This modulates the magnetic field in fixed coils.

The result is lower moving mass than MM designs, offering improved transient response and a more refined sound. At the same time, MI cartridges retain MM-like output levels and user-friendly operation.

Inductance Considerations:

MI cartridges typically exhibit somewhat lower inductance than MM designs, but they still behave as RLC circuits where capacitance loading can shape the top-end response. Like MM cartridges, MI designs may benefit from thoughtful matching with cables and phono stages to optimize high-frequency clarity.

For Analog Lovers seeking an elegant balance between performance and convenience, MI phono cartridges are worth serious consideration.

Moving Coil (MC) Cartridges

MC cartridges represent the pinnacle of analog playback for many Analog Lovers.

Here, the coils themselves move within a fixed magnetic field. The moving mass is extremely low, allowing the stylus to trace the finest nuances of a record groove with astonishing fidelity.

MC cartridges divide into two categories:

-

Low Output MC: around 0.2 to 0.5 mV, requiring dedicated MC amplification or a Step-Up Transformer.

-

High Output MC: around 2 to 2.5 mV, compatible with MM phono stages, offering excellent performance with greater flexibility.

Inductance Considerations:

MC cartridges use very small coils and therefore exhibit extremely low inductance. The resonant frequency of the RLC circuit is pushed well into the ultrasonic range, making MC cartridges largely immune to changes in cable or phono stage capacitance. This results in a flatter, more extended frequency response and greater freedom in system matching.

Additionally, smaller coils also mean less crosstalk between stereo channels, resulting in improved channel separation (often +10 dB or more compared to MM designs). The acoustic benefit is greater stereo imaging precision, one of the qualities that give MC phono cartridges their renowned sense of space and realism.

Why do MC phono cartridges dominate high-end systems?

Because they enable a more faithful conversion of groove velocity to electrical signal, offering lower moving mass, higher linearity, flatter response, and greater stereo separation. The subtleties of timing, space, and harmonic complexity are preserved with greater integrity.

Stylus Shape Comparison

Phono Cartridge Main Stylus Shapes

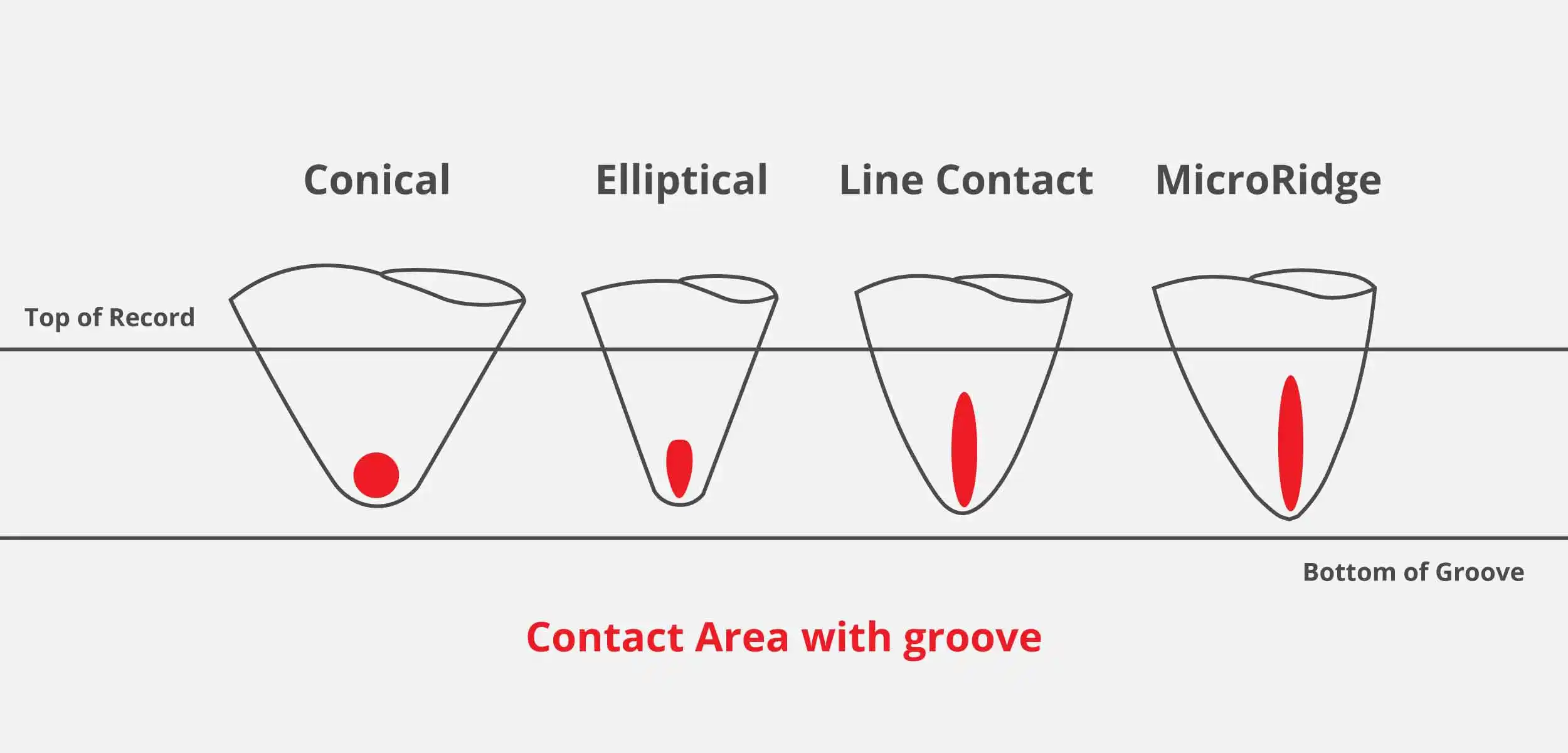

The shape of the stylus determines how much groove information is retrieved, how well the stylus tracks complex modulations, and how gracefully it handles wear — both of the groove and the stylus itself.

Broadly speaking, more advanced stylus shapes offer greater resolution and lower distortion, but often require more precise setup to perform at their best. One key factor is Vertical Tracking Angle (VTA): the more sophisticated the stylus profile, the more sensitive it becomes to VTA alignment for optimal sound.

Here is a comparison of common stylus shapes:

Conical (Spherical)

The simplest and most forgiving shape. The stylus contacts the groove at a single point, making it tolerant of imperfect setup. However, it cannot retrieve the finer details encoded in the groove, and high-frequency tracking is limited. Conical styli are well suited to casual listening and DJing with heavy back-cueing and even scratching.

Elliptical

A significant step up from conical. The elliptical stylus contacts the groove along a narrow vertical band, allowing it to trace modulations with better precision, particularly at higher frequencies. Good MM cartridges commonly use elliptical styli, offering excellent value and sound quality.

Hyperelliptical / Line Contact / Shibata

These advanced profiles extend the contact area along the groove walls, allowing the stylus to follow groove modulations with far greater accuracy. This results in lower distortion, improved tracking, and reduced record wear. However, these shapes are more sensitive to VTA and azimuth alignment, and require more careful setup to reach their full potential.

MicroRidge / MicroLine

Among the most sophisticated shapes available, MicroRidge and MicroLine profiles closely replicate the shape of the original record cutting stylus. They deliver exceptional detail retrieval, and extended frequency response. These profiles are the most sensitive to setup, particularly VTA, and are best suited to experienced listeners who can carefully fine-tune their systems.

Finding the Sweet Spot:

For many Analog Lovers, a Line Contact stylus strikes the ideal balance. It offers compelling detail retrieval and excellent tracking with significantly lower distortion than elliptical shapes, yet remains more forgiving in setup than the most extreme profiles. Properly aligned, a Line Contact stylus can deliver musical richness, resolution, and groove preservation that elevate the analog experience without becoming a chore to optimize.

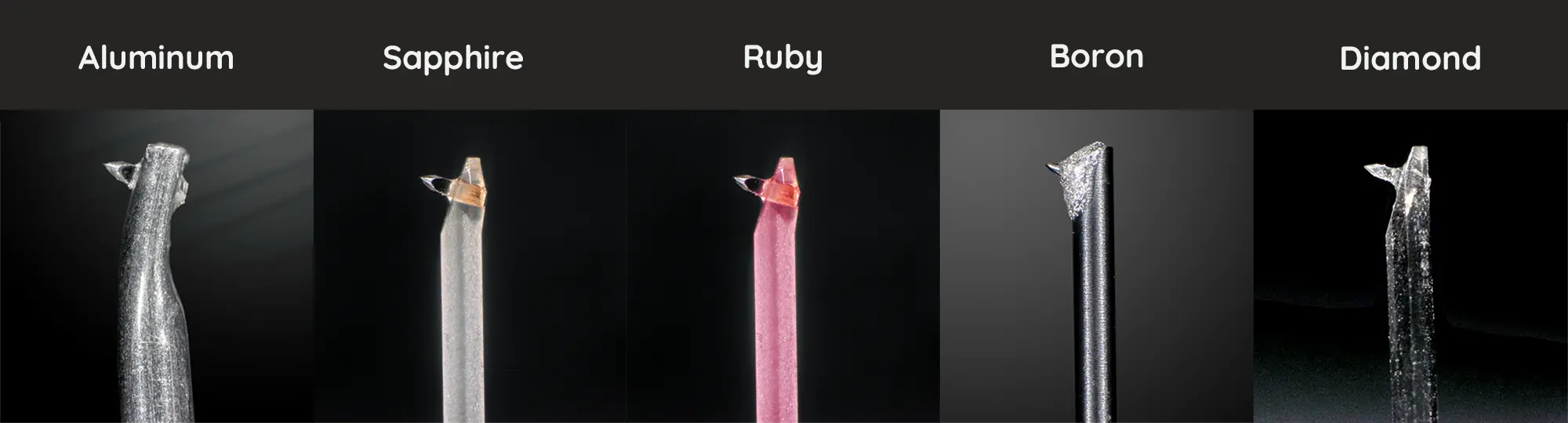

Cantilever Material Comparison

Phono Cartridge Main Cantilever Materials

The cantilever acts as the mechanical bridge between the stylus and the generator system, transmitting the minute groove modulations with precision and speed.

The choice of cantilever material directly influences the cartridge’s:

-

Speed and transient response

-

Resolution and clarity

-

Tonality and musical character

-

Susceptibility to resonance and coloration

Ideally, the cantilever should be as light, rigid, and well-damped as possible, minimizing unwanted resonances and faithfully transmitting stylus motion to the generator.

Here is a comparison of common cantilever materials:

Aluminum

Still widely used in many MM and entry-level MC cartridges. Aluminum is inexpensive and easy to manufacture, offering good basic performance. However, it is relatively soft and can exhibit internal resonance and flexing, which may introduce subtle coloration and limit ultimate detail retrieval.

Sapphire

Extremely rigid and hard, sapphire provides very high resolution and excellent tracking precision. However, it can sometimes lend the sound a slightly cooler or more analytical character, depending on the overall cartridge design.

Ruby

Similar in performance to sapphire, ruby adds a subtle sense of crystalline precision to the sound. It is less commonly used today but remains a beautiful and highly resolving material in the right implementation.

Boron

Boron has become the reference material in many of the best high-end MC designs. It is very stiff, extremely light, and has excellent internal damping properties. This allows for fast transient response, clean articulation, and a natural tonal balance. Boron cantilevers offer an excellent combination of performance and practicality.

Diamond

At the top of the hierarchy, a solid diamond cantilever offers unmatched stiffness, the lowest possible moving mass, and the purest transmission of stylus motion. It can deliver astounding clarity, microdynamic precision, and an uncanny sense of space and transparency. However, it is extremely difficult and expensive to manufacture, and is reserved for the cost-no-object phono cartridges.

Finding the Sweet Spot:

For most Analog Lovers, boron strikes the ideal balance. It combines exceptional rigidity and speed with musicality and ease of integration into a wide range of system designs. This is why it is the material of choice in many of today’s most respected high-performance MC cartridges, including those from Le Son.

Phono Cartridge Matching: Tonearm, Compliance, and Resonance

Low Compliance (Ortofon SPU Royal GM MKII) and Medium Compliance (Le Son LS10) Cartridges

Choosing a cartridge is not just about its inherent qualities. It must also form a harmonious partnership with your tonearm and phono stage.

Every tonearm has an effective mass. Every cartridge has a compliance — a measure of how easily its suspension allows the stylus to move in response to groove modulations. Together, these two factors form a mechanical resonance system, with a natural resonant frequency typically between 7 and 12 Hz for optimal results.

If the resonance frequency is too low (below 7 Hz), the system may become susceptible to record warps, footfalls, and other low-frequency disturbances. If the resonance is too high (above 12 Hz), audible coloration and tracking errors can occur, particularly with challenging recordings.

Matching compliance to tonearm effective mass is therefore critical:

-

Heavy-mass tonearms pair best with low-compliance cartridges.

-

Light-mass tonearms favor high-compliance cartridges.

Compliance is typically expressed in units of µm/mN (micrometers per millinewton), most often measured at 10 Hz.

To simplify matching, there are excellent online tools available. The Cartridge / Tonearm Resonance Calculator at VinylEngine.com is particularly convenient and accurate. By entering your tonearm’s effective mass and your cartridge’s compliance and weight, you can easily visualize the system’s resonant frequency — and determine whether your combination is well-matched.

Example:

The Le Son LS10 MKII cartridge has a compliance of 15 µm/mN @ 10 Hz and weighs 8.9 grams with its fixing screws, making it an ideal match for tonearms with an effective mass ranging between 5 and 20 grams — which covers many popular mid-mass tonearms used in both modern and vintage high-quality turntables.

Taking the time to match your cartridge and tonearm carefully will reward you with:

-

Improved tracking on challenging records

-

Lower distortion and coloration

-

Greater bass articulation and midrange clarity

-

Better groove preservation over time

System synergy is where true analog magic happens.

Resonance, Damping, and Groove Wear: How Cartridge Design and Setup Protect Your Records

Every phono cartridge is a finely tuned mechanical system. The way it manages resonance, damping, and stylus-groove interaction directly shapes not only sound quality, but also record longevity.

For discerning Analog Lovers, understanding this relationship is key to both sonic satisfaction and record preservation.

High-Frequency Resonance and Damping

The Effective Tip Mass (ETM) of the cartridge, combined with the elasticity of the vinyl groove, forms a high-frequency resonance system. The groove acts as a spring, while the stylus-cantilever assembly provides the moving mass. This produces a natural resonance, typically between 15 and 50 kHz in modern cartridges.

Since vinyl elasticity is essentially constant, this resonant frequency depends almost entirely on ETM:

-

Lower ETM → higher resonance, better transient response, cleaner sound.

-

Higher ETM → lower resonance, with increased risk of distortion and groove wear.

As this resonance is approached, out-of-phase motion develops between the stylus and the groove:

-

The stylus may move disproportionately compared to the actual modulation, creating a peak in the frequency response.

-

Above this point, response falls off sharply, causing a loss of air and detail.

Even more critically, out-of-phase motion affects stylus pressure:

-

Pressure peaks can cause plastic deformation of the vinyl.

-

Loss of contact can occur, with the stylus briefly “floating” and then re-engaging the groove, risking localized damage.

In poorly damped cartridges with high ETM, this can result in measurable wear, sometimes leaving a visible “footprint” in the groove after only a few plays.

The Role of Damping

To manage this, well-designed cartridges carefully control damping:

-

The suspension elastomer — which centers and supports the cantilever — is tuned to provide optimal damping at resonance.

-

Proper damping prevents sharp resonance peaks, ensures stable stylus pressure across the audio band, and minimizes out-of-phase effects.

This is a delicate balance. Too much damping can rob the music of life and microdynamics. Too little damping risks harshness, ringing, and groove damage.

How Cartridge Design Affects Groove Wear

Beyond resonance management, several aspects of cartridge design directly influence how safely the stylus navigates the groove:

-

Stylus profile: Advanced shapes (Line Contact, Shibata, MicroRidge) distribute force over a larger contact area, reducing peak pressure and groove wear.

-

Effective Tip Mass (ETM): Lower ETM enables the stylus to track fast modulations more accurately and safely.

-

Cantilever material and suspension: A stiff, well-damped cantilever with optimized compliance maintains stable groove contact even during challenging passages.

-

Stylus polish and condition: A perfectly polished, well-maintained stylus minimizes friction. A worn or damaged stylus, even at correct VTF, can rapidly degrade records.

The Role of Proper Setup

Even the finest cartridge requires careful setup to protect your records and unlock the cartridge’s full potential:

-

Vertical Tracking Force (VTF): Too low risks mistracking and impact damage; too high increases groove pressure and wear. Always use a calibrated gauge to set VTF exactly as recommended.

-

Vertical Tracking Angle (VTA): VTA determines the stylus rake angle relative to the groove. Advanced stylus profiles (Line Contact, Shibata, MicroRidge) are especially sensitive to VTA. Incorrect VTA can increase groove wear and compromise detail retrieval. Start with the tonearm parallel to the record and fine-tune by ear and measurement for optimal balance.

-

Alignment and Azimuth: Correct alignment ensures balanced contact across both groove walls, preventing asymmetric wear and distortion.

-

Anti-skating: Proper anti-skate adjustment maintains even lateral pressure, avoiding uneven groove wear and channel imbalance.

A well-designed, properly set up cartridge allows your stylus to trace the groove with both precision and care:

-

It minimizes high-pressure contact points.

-

It maintains stable, centered contact during all types of modulation.

-

It dramatically extends the life of your records, letting you enjoy them for decades.

In contrast, a poorly chosen or misaligned cartridge, or a worn stylus, can cause permanent damage in just a few plays.

At Le Son, we design our cartridges with this philosophy in mind: to reveal the soul of music, while treating your records with the utmost respect. A great cartridge is not only about sound, it is also about preserving the art it plays.

Conclusion

The phono cartridge is where music begins. Its ability to translate the etched vibrations of a groove into an electrical signal determines everything that follows.

In choosing a cartridge, you are not merely selecting a product. You are choosing how you will experience your records, how deeply you will hear, and how fully you will feel.

At Le Son, we believe in the power of analog sound to connect us with the spirit of music. We create our cartridges for those we call Analog Lovers — listeners who cherish the human, the tactile, the timeless essence of vinyl.

FREQUENTLY ASKED QUESTIONS

- What is the difference between MM, MI, and MC phono cartridges?

- What role does compliance play in phono cartridge choice?

- How does cantilever material affect phono cartridge sound?

- Which stylus shape is best for high-end playback?

MM (Moving Magnet) phono cartridges move a magnet between fixed coils. MI (Moving Iron) phono cartridges move a lightweight iron element to modulate a magnetic field. MC (Moving Coil) phono cartridges move coils themselves within a fixed magnetic field.

MC designs — especially Low Output MC — offer the highest sonic potential. MI provides an excellent balance of performance and convenience. MM remains a practical and rewarding choice.

Compliance must match your tonearm’s effective mass to achieve an optimal resonance frequency (typically between 7 and 12 Hz). A poor match can degrade tracking ability, increase distortion, and reduce musical clarity.

The cantilever material directly influences how accurately the phono cartridge transmits groove modulations. Stiffer, lower-mass materials such as boron and solid diamond provide superior transient speed, detail retrieval, and clarity. Aluminum offers good value but can introduce subtle coloration and limit ultimate resolution.

Advanced profiles such as Line Contact, Shibata, or MicroRidge provide the most precise groove tracing and the lowest distortion, making them ideal for Analog Lovers with well-curated vinyl collections and systems capable of revealing fine musical nuance.

Join Our Community!

Subscribe to La Newsletter

Stay informed with the latest news and blog posts from the world of high fidelity sound.

Gregory de Richemont

Gregory de Richemont is the founder of Le Son, where high-fidelity sound meets emotional depth. Blending a background in global business with a lifelong passion for analog, Gregory left the corporate world to follow the call of pure sound. His work is dedicated to creating listening experiences that don’t just impress — they move. Learn more on our About Us page.