Set Vertical Tracking Angle – Measure & Adjust The VTA in 3 Steps

At Le Son, we design and manufacture MC Cartridges, so we install and align cartridges on a regular basis. We often receive questions from customers on how to setup their phono cartridge VTA properly, so we decided to share our insights and setup method here.

In this post, we will first explain what actually is Vertical Tracking Angle (VTA). Then, we will discuss how important VTA is for the sound quality of your system. And finally, we will share our 3-step method for adjusting and measuring VTA.

The time you invest in mastering this subject will be rewarded with the magic of great analog sound, as well as longer stylus and record life.

Ready?

Let’s get started!

Vertical Tracking Angle: Introduction

First, let’s clarify what Vertical Tracking Angle (VTA) is.

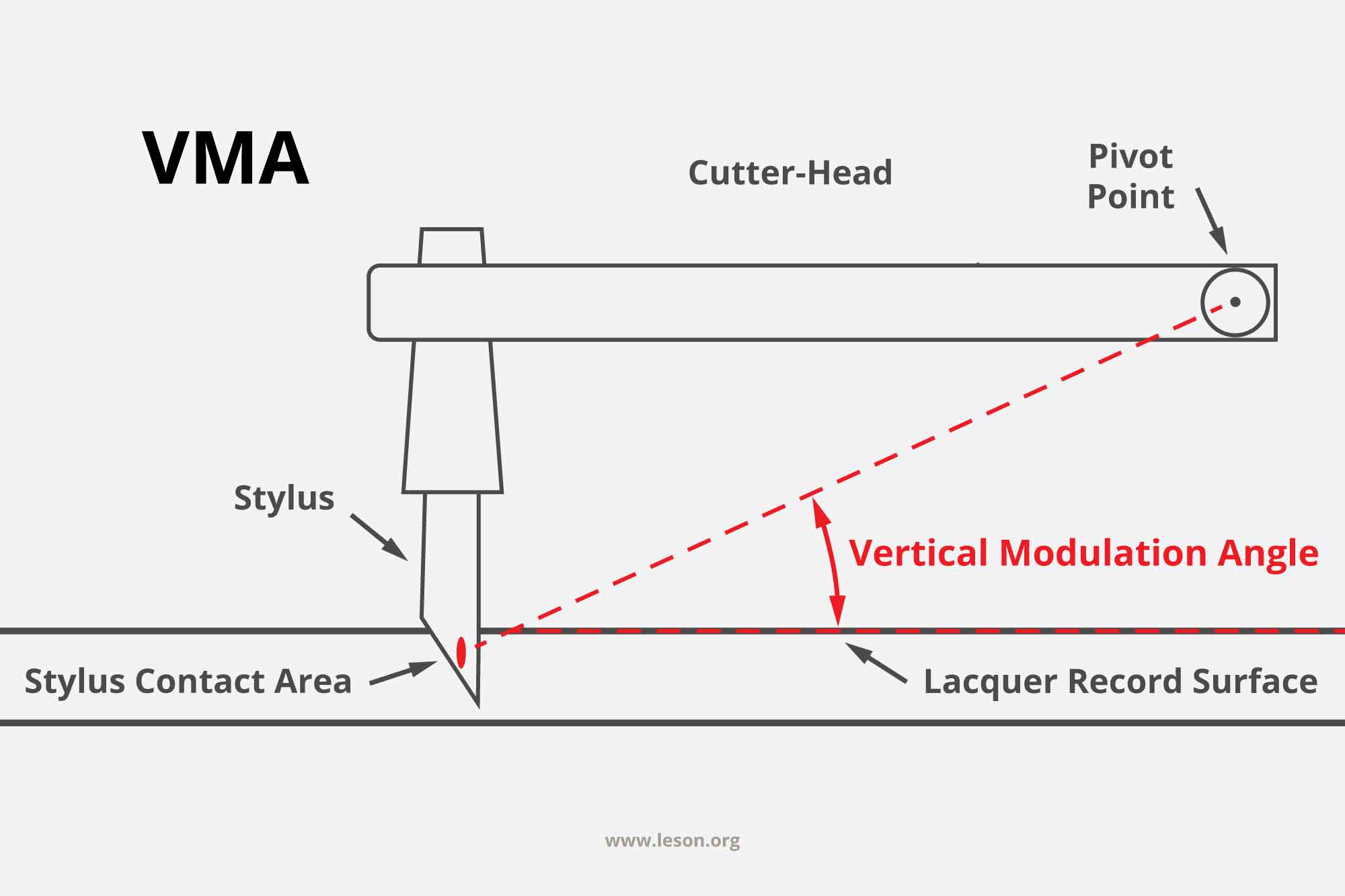

Physically, the VTA is the angle formed by the record surface and the line defined by the contact area of the stylus in the groove and the pivot point of the cantilever.

The nominal goal of measuring Vertical Tracking Angle (VTA) is to have the playback angle match the recording angle of the record lathe cutter-head.

On a record lathe, the cutting angle is also called Vertical Modulation Angle (VMA). It refers to the angle formed by the lacquer disc surface and the line defined by the contact area of the cutter stylus and the pivot point of the cutter head.

The difference between the VTA and the VMA is called the Vertical Tracking Error.

Ok great, we understand what VTA is.

Now let’s discuss how important the VTA is in getting the most out of your phono cartridge.

VTA Importance: Mono vs Stereo Cartridges

With the introduction of stereo records, both the design of the record lathe cutter-heads and the phono cartridges able to read this extra information became more sophisticated.

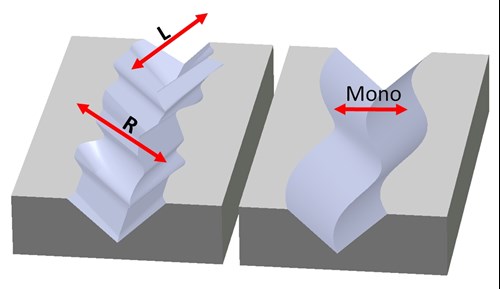

In addition to lateral movements of the groove in a mono record, a stereo disc includes vertical modulation of the groove depth, which distributes the mono information into the left and right channels.

Since there is no vertical modulation of the stylus on mono records, VTA is not relevant for mono cartridges.

VTA is therefore only an issue for stereo cartridges.

VTA Importance: Stereo Cartridges

One important thing to understand is that there is no such thing as definitive VTA setting.

The main reason being there is no standardised Vertical Modulation Angle (VMA) on record cutting lathes. Since 1965 onwards, the VMA varies between 15 ° and 22 °, depending on the lathe system. The “perfect” VTA setting is therefore different from one record to the other, and cannot be perfect for all.

So how do we deal with this problem? What is the threshold at which the distortion due to Vertical Tracking Error becomes audible?

In practice, a Vertical Tracking Error limit of 10 degrees is a great starting point for optimum playback quality. Knowing that the VMA of most records is between 15 degrees and 26 degrees, a modern cartridge should have a VTA below 25 degrees. Nowadays, the generally accepted optimum VTA value for a stereo cartridge is 20 degrees.

If your phono cartridge is designed properly, the VTA mentioned on its specification sheet should be attained when the tonearm is parallel to the record surface. As mentioned earlier, it is not necessary to be extremely precise here, as VTA is a moving target. Once your tonearm is parallel to your record, you are all set for VTA.

Ok we are almost done with VTA now.

But not completely.

Depending on the shape of your cartridge stylus, there is a parameter called Stylus Rake Angle (SRA) that can be of tremendous importance to get the best out of your cartridge.

Let’s see that together!

VTA Importance: Stylus Rake Angle (SRA)

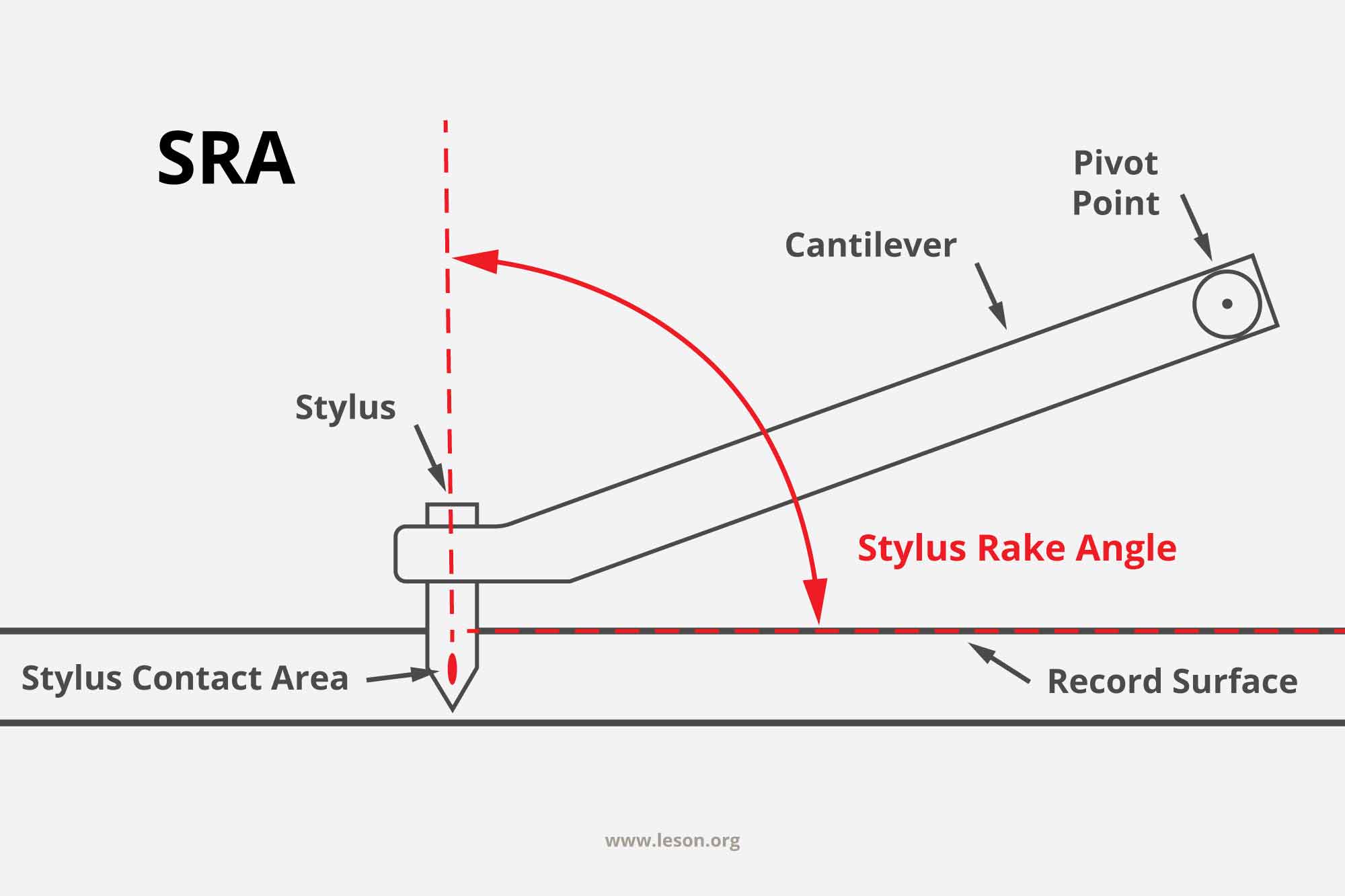

The Stylus Rake Angle (SRA) is the angle formed by the vertical centerline that the stylus contact areas make with the groove ridges, and the record surface.

As you can see on the above drawing, Vertical Tracking Angle (VTA) and Stylus Rake Angle (SRA) are dependent on one another. If you increase VTA by rising the tonearm pivot point, you increase SRA as well.

Stylus Rake Angle (SRA) exists as on a record cutting lathe, the cutter-head stylus needs to have a slight angle above 90 degrees (generally 91 to 95 degrees) relative to the record surface in order to facilitate lacquer “chip” (cutaway strand) removal.

As we now know, the VTA and the SRA have a fixed relationship, so when we alter VTA, we also adjust SRA, and the two words are somehow interchangeable.

The importance of the SRA depends on the cartridge stylus shape.

On any phono cartridge, the stylus shape is a paramount feature. The closer it is from the shape of a cutter-head stylus, the better it will fit in the record grooves and retrieve the musical information.

Basic cartridges will feature a conical stylus, while better cartridges will feature the best Line Contact stylus shapes.

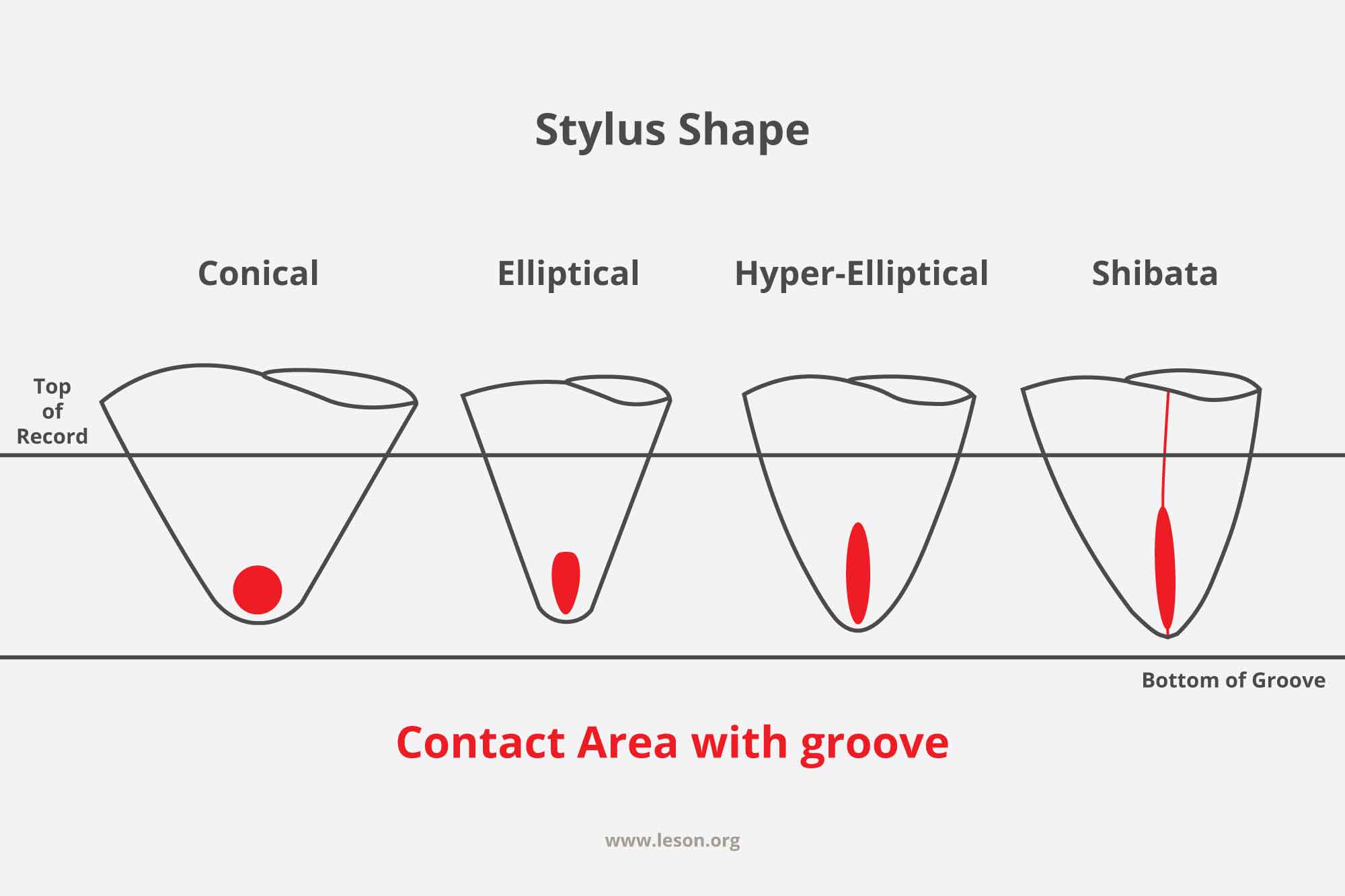

In the below drawing, you can see the contact area of the main stylus shapes featured on modern phono cartridges:

The Shibata stylus shape shows the longest, narrowest contact area, while the conical stylus has a small circular contact area. In general, conical and elliptical stylus shapes are called “Point Contact”, while hyper-elliptical and Shibata-like stylus shapes are called “Line Contact”.

The Stylus Rake Angle (SRA) becomes more and more important as the stylus shape gets better. SRA is inexistent with conical styli, and extremely important with Shibata styli.

When the SRA is incorrect with a Line Contact stylus shape, the edges of the stylus can catch the groove modulations and send vibrational shocks up the cantilever. This can result in higher distortion than a simple conical stylus!

And when the SRA is correct with a Line Contact stylus shape, everything falls into place, and the magic of great analog sound unfolds.

VTA Importance: Summary

On most cartridges, the Vertical Tracking Angle (VTA) is correct when the tonearm is parallel to the record.

If your cartridge stylus shape is hyper-elliptical or better (Line Contact family), you must fine-tune the VTA to find the proper Stylus Rake Angle (SRA). Only then will your cartridge work its magic.

All right, it is now time to share with you our 3-step method to adjust VTA and get the best out of your cartridge!

Set Vertical Tracking Angle: 3-Step Method To Adjust & Measure VTA

This method uses the ultimate measuring tool there is for such a purpose: your ears.

Trust your ears over any other fancy tools. You can perfectly do this without a microscope to measure a 92 degree angle, a software prone to programming errors, or an intermodulation distortion (IMD) tester.

Yes, your cartridge should produce the lowest intermodulation distortion, and you can measure the second harmonic distortion from a test record. These tools may be useful, but when you lower the stylus on the record, your ears are the ultimate authority to decide if the sound is great or not!

What You Need for VTA / SRA fine-tuning:

A great sounding LP record, preferably featuring acoustic instruments. The record pressing needs to be above all suspicion; otherwise, you may jeopardize the VTA / SRA setting.

The necessary tool(s) to adjust your tonearm height.

Time, patience, and peace of mind.

Step 1: Get The Basics In Place

The following are the fundamentals for optimal turntable performance:

Your turntable is leveled.

Your cartridge is correctly aligned in terms of overhang and tilt. To do so, we recommend using a cartridge alignment protractor.

The azimuth angle is correct: when you look at the cartridge from the front, the angle the cartridge cantilever makes with the surface of the disc should be 90 degrees. On most cases, azimuth is correct with the turntable factory settings.

The Vertical Tracking Force (VTF) is set to the optimum value. Begin with the value recommended on your cartridge specifications sheet. Increase the VTF if the sounds is too bright, has little bass, and the midrange sounds hollow and empty. Reduce the VTF if the bass becomes muddy, the treble becomes dull, and the sound loses air.

The anti-skating is properly set. We recommend using a mono recording to do so. The solo voice or instrument should be centered when the antiskating value is correct.

The tonearm is parallel to the record when the cartridge is reading the record. You can use a VTA / Azimuth Alignment Gauge Block or just use your eyes.

If your cartridge stylus shape is conical or elliptical, you can stop here. You are all set.

If your cartridge stylus shape is hyper-elliptical or better, you can proceed to VTA / SRA fine-tuning.

Step 2: Measure VTA / SRA

Play your great sounding record, and listen carefully.

If the sound is too thin, the midrange lacks body, and the low end lacks heft and weight, your tonearm is too high.

If the sound is too bright and lacks transparency, your tonearm is too low.

The next point will be to adjust tonearm height accordingly.

Step 3: Adjust VTA / SRA

By raising and lowering the height of the tonearm pivot, you will fine-tune the angle of the tonearm and trigger changes in tracking angle / SRA.

We recommend to change the tonearm height by very small increments, and return to Step 2.

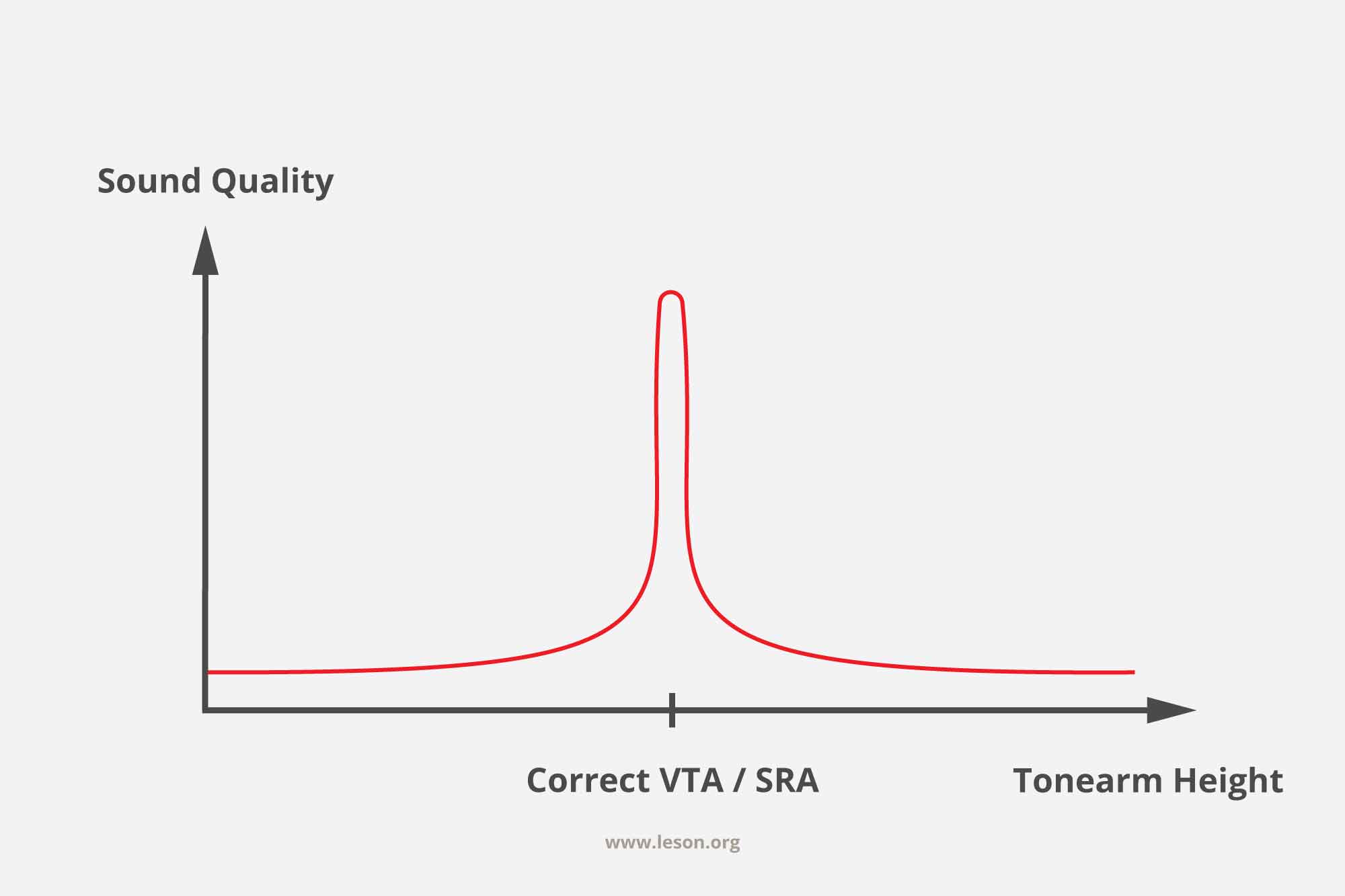

Note that the correct SRA value is quite narrow, and the VTA / SRA fine tuning could be represented like this:

If the VTA / SRA is correct, the sound will fall into place, and the magic will unfold!

Vertical Tracking Angle: Conclusion

This is it for this blog post about the importance of VTA and how to get it right.

If you expect to unlock all the performance promised by your high-end phono cartridge, this adjustment is paramount.

The above method gives you everything you need to know to unfold the magic of great analog sound.

And it is my dearest wish that you succeed!

Vertical Tracking Angle: Frequently Asked Questions

Does Vertical Tracking Angle (VTA) influence Vertical Tracking Force (VTF)?

Yes VTA has an influence on downforce, and vice versa. The amount of influence mainly depends on the tonearm length. The longer the tonearm, the less influence.

Generally speaking, if your pickup arm is parallel to the record when you begin adjusting VTA, there should not be a noticeable difference in VTF once you have discovered the correct VTA.

Does Record Thickness influence VTA?

Yes, record thickness influences VTA. The longer your tonearm is, the less impact record thickness will have on your cartridge VTA.

If your tonearm has an easy VTA adjustment, you can find the best pivot height for each record thickness. Otherwise it is a matter of compromise.

Do I need a Vertical Tracking Angle Gauge?

VTA Gauges are affordable and convenient tools. They allow to read if the tonearm, when viewed from the side, is parallel to the platter / record.

Performing this measurement is easy, however the gauge may damage the surface of the record when placed on it.

Furthermore, if you have a Line Contact stylus, you will still need to fine-tune your arm height to get the best out of your cartridge. Your ears are the best hi-fi tool for this purpose!

How To Set Vertical Tracking Angle On Technics 1200?

To adjust the VTA on a Technics 1200, first you need to release the arm lock.

Then, you can simply adjust the tonearm pivot height by rotating the arm-height control ring.

Once finished, lock the tonearm height by turning the arm lock knob. Done!

How To Determine Best Vertical Tracking Angle Using Audacity?

Audacity is a great software, but we don’t think it is the right tool to determine the best actual VTA.

Your ears, however, are perfectly suited for the job if you allow them to guide you!

Credits:

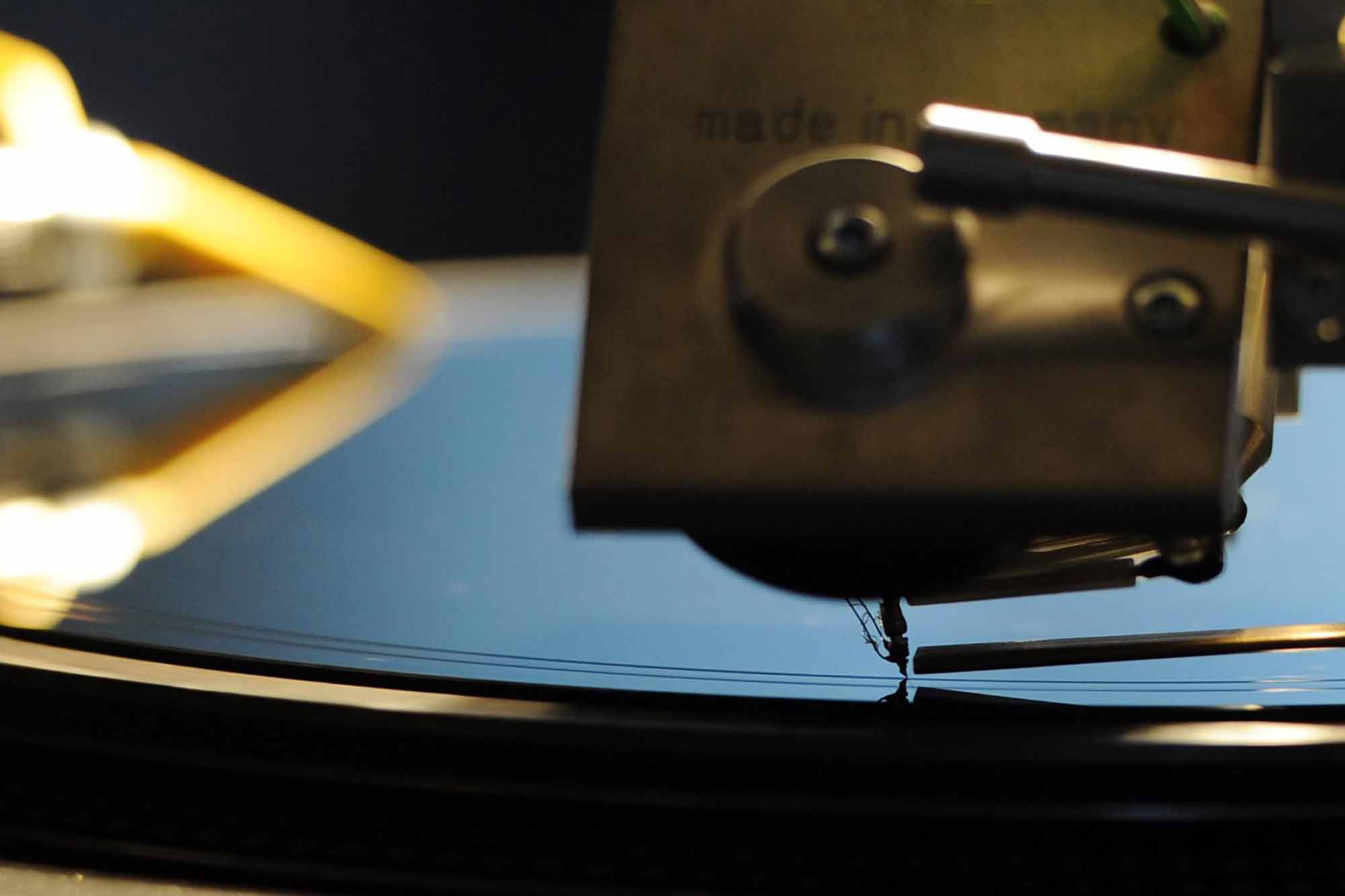

All pictures on this blog post are credited to The Vinyl Factory, which is a remarkable pressing plant in the United Kingdom. Located in Hayes in West London, the plant features the original machinery used to press The Beatles, Pink Floyd, Sex Pistols and many more of the most emblematic records in history.

Join Our Community!

Subscribe to La Newsletter

Stay informed with the latest news and blog posts from the world of high fidelity sound.

Gregory de Richemont

At the helm of Le Son, Gregory combines his business administration expertise with a deep passion for high fidelity sound. Renowned for his skill in analog audio, Gregory's journey from corporate life to audiophile expert is a testament to his dedication to pure sound. Discover more on our About Us page.